Compared to this type.

There is no comparison

RevCongratulations !

You have found the ultimate in low profile CNC clamps.

These “ultra low profile” clamps will save you money on the bits you will now no longer break by running into those other clamps.

It can cost you 20 to 100 dollars for even the most ordinary bit like a 1/8” endmill, a v bit, or a bowl bit. And even if you get one from a company that guarantees replacement if you break it, you can't get anyone to replace the time and materials you lose every time it happens.

These clamps can help you to avoid this. We don't guarantee you won’t do something silly, but with thoughtful use and care, you can greatly reduce these incidents by using these clamps. As I am fond of saying “You can't hit it if it isn't there. And that is the beauty of HillJack Fabrication's “ultra low profile clamps”.

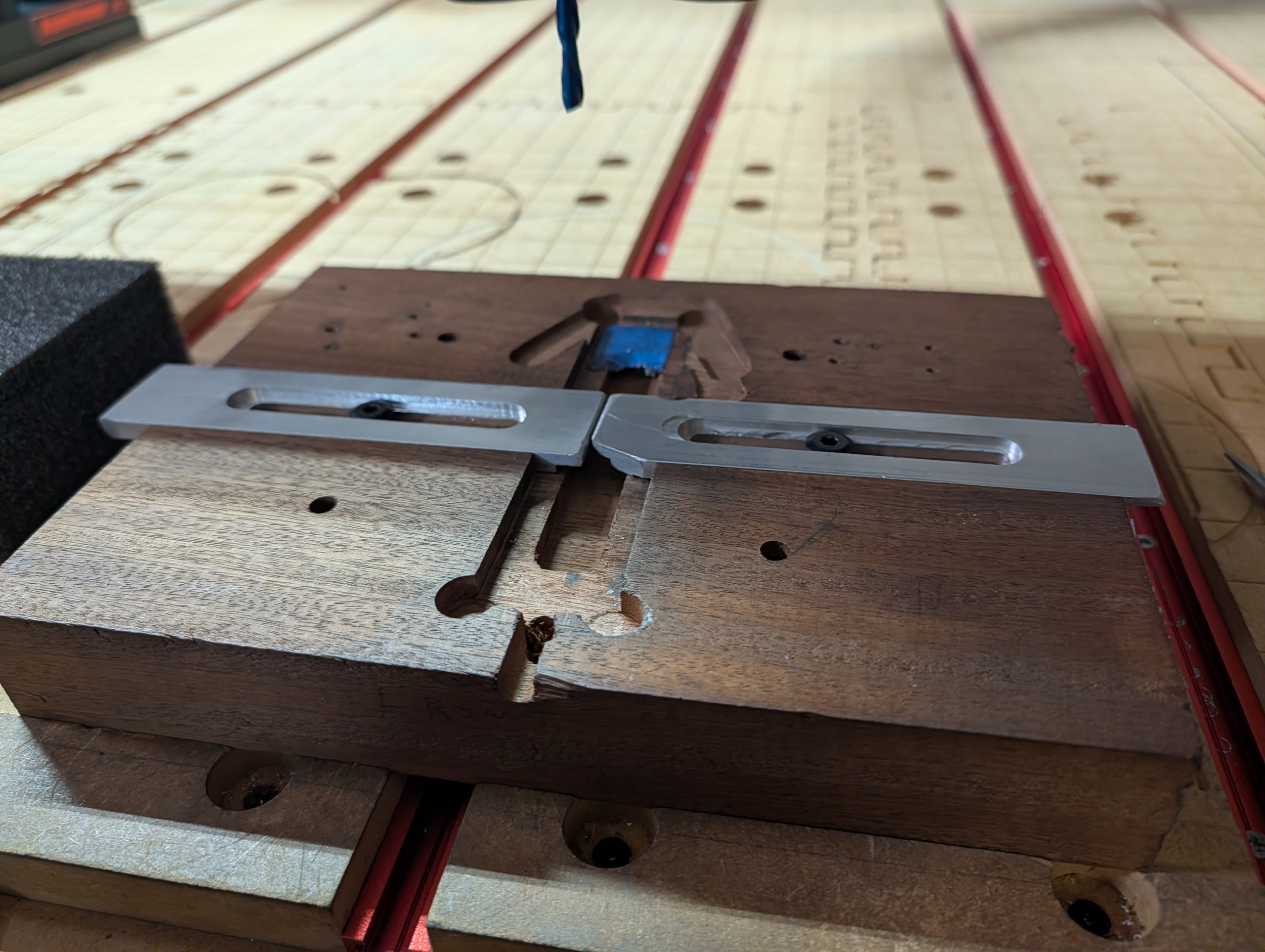

See the following illustration as to the suggested use of these clamps.

Your set comes with a full set of 4 clamp bars, four “beefy t nuts”, a hex tightening tool,

and three size ranges of specially designed low head hold down screws.

These sizes can be used for various thicknesses of your carving material. Up to over an inch thickness. Other screw sizes are available for even larger stock. Just go on Amazon or most bolt/hardware dealers and choose the flat head “furniture connector” type screws. These clamps were designed to use these low head screws.

Please note: the t nuts will fit both standard and Onefinity t tracks

You can also use these clamps to make your fixtures even more useful by installing them in your fixture just drill a hole for a press fit for a Beefy T nut through you fixture and carve out a slot in the bottom of your fixture as shown below in our example. For the ultimate in repeatability for those ongoing Jobs, making them far easier to do multiples of the same product. Making life much easier and improving your workflow as well. use in conjunction with locator pins it make repeatable setups virtually quick and painless. You can see the four holes for the locator pins add them to your work program

We wish you well in your CNC adventure.

See the video here Hilljack Clamps

https://www.youtube.com/watch?v=PPTUbtQp74U

Robert Mainville

HillJack Fabrication

hilljackfab.comolutionizing Design with Advanced CAD CAM Solutions